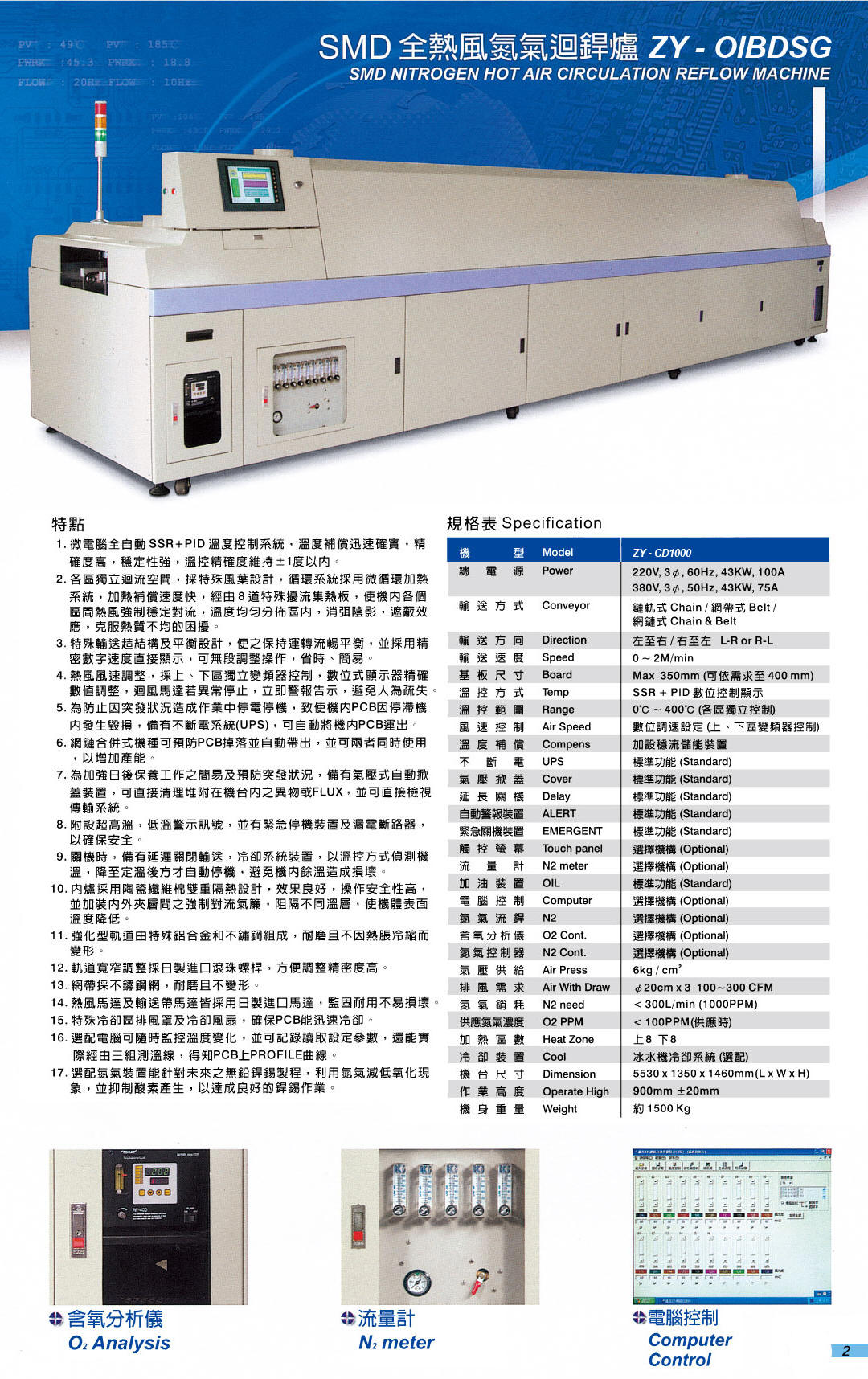

ZY-OIBDSG Features :

1.

Microcomputer fully automatic SSR+ PID

thermo-control system to make up temperature in

a speedier and exact way. Higher

accuracy and stronger stability to maintain thermo-control

accuracy within

¡Ó

1 degree.

2.

Independent circuit space is provided in each

zone. Through three specific turbulent heat-

collecting plate, compulsory

stabilized hot air convection is achieved between each

compartment inside the

machine. The temperature is distributed to each zone uniformly to

eliminate

shade and sheltering effect and overcome the annoyance of uneven heating.

3.

Specific conveying structure and balance design

work to keep smooth and balanced

operation. Further, precision digit is

displayed in an instant and direct manner to facilitate

non-speed adjustment and

operation, time saving and convenient.

4.

Hot air speed adjustment is controlled by

independent upper and lower zone frequency

changers. Digital display is

available for value accuracy adjustment to send out alarm

immediately should an

abnormal shutdown of the circuit motor happen so as to avoid man-

caused

negligence.

5.

To prevent downtime due to power shutdown caused

by contingencies during the operation,

which may result in damages to the PCB,

an UPS system is prepared to send out the PCB

automatically.

6.

Online-linking model is designed to prevent PCB

from dropping and for automatic sending out.

In the meantime, both functions can

be used simultaneously to enhance the productivity.

7.

For convenient maintenance work and preventing

contingencies in future, compressed air

automatic lid-pulling device is provided

for direct cleaning of foreign objects or FLUX gathered

inside the machine and

for direct inspection of the transmitting system.

8.

Extreme and low temperature alarm signals are

designed with an emergency shutdown device

and a leakage breaker provided to

ensure safety.

9.

To switch off machine, relay switch conveying

and cooling system are provided to detect the

temperature of machine by means of

thermo ¡Econtrol

so that the machine will be turned off

automatically after being cooled down to

constant temperature to avoid damages as may be

caused by residual temperature

inside the machine.

10. Double layer heat insulation design in ceramic and

fiber asbestos is used inside the furnace

to provide better effect and

higher safety in operation. In addition, additional compulsory

convection air

curtain is also installed between internal and external linings to separate

different thermo layers so as to bring down the surface temperature of the

machine.

11.

Reinforced track made of special aluminum alloy

and stainless steel is installed, which is

abrasion resistant without deformation due to heat expansion and cold

shrinking effect.

12.

The track gauge is adjusted by the imported

Japanese ball screw to facilitate adjustment

with higher precision as well.

13. Mesh belt is made stainless steel, abrasion resistant without deformation.

14.

Hot air motor and conveyor motor are imported

from Japan. Rigid, durable and longer

lasting.

15.

Ventilation mask and cooling fan are Installed

Iii the special cooling zone to ensure speedier

cooling of PCB.

16.

Optional computer can be used to monitor the

temperature change at any time. It can record

and read the programmed parameters

and further, the Profile Curve on PCB can be learned

through three sets of

thermo-testing lines.

17.

Optional nitrogen device is provided for use in

the future flux-free soldering process, thus

reducing the oxidization phenomenon

and inhibiting the production of acid content for

achieving a better soldering

operation.